- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Project Information | ||

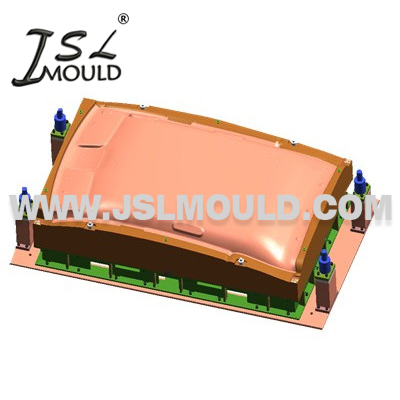

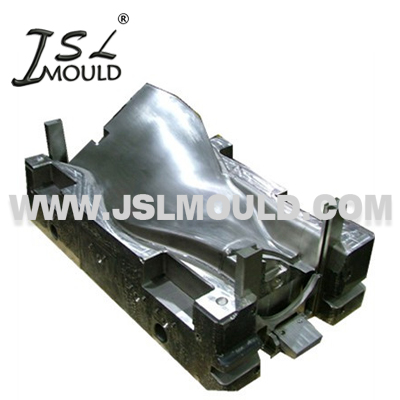

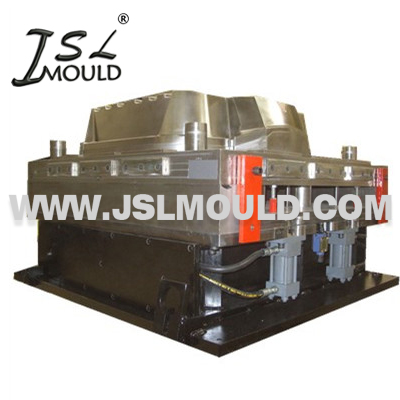

| Product Description | Part Name | Automotive windscreen Wiper |

| Part Material | LFT | |

| Part Size(MM) | 1232*240*123 | |

| Mould Steel | A plate | S50C |

| B plate | S50C | |

| Cavity Insert | 718 (HRC 34-38) | |

| Core Insert | 718 (HRC 34-38) | |

| Slider Insert | / | |

| Ejector Plate | S50C | |

| Spare Parts | S50C | |

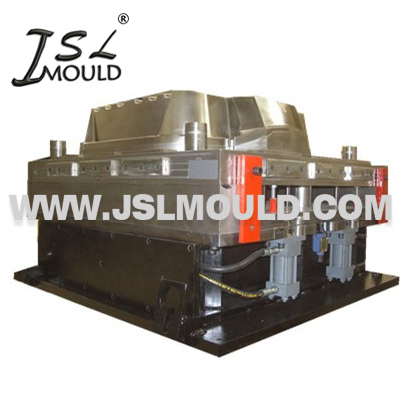

| Mould Description | Mould Size (L*W*H MM) | 1500*740*625 |

| Mould Gross Weight (KG’s) | 5000KG | |

| Mould Life Time (Shots) | 300,000 | |

| Mould Manufacturing Cycle | 60 days | |

| Surface Finish | polishing | |

| Runner Description | / | |

| Injection Gate Type | / | |

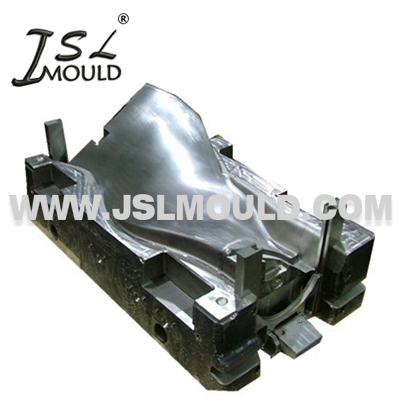

| Ejection System | Oil cylinder | |

| Cycle Time (Second) | 120s | |

| Compressionmoulding machine | 600T | |