- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

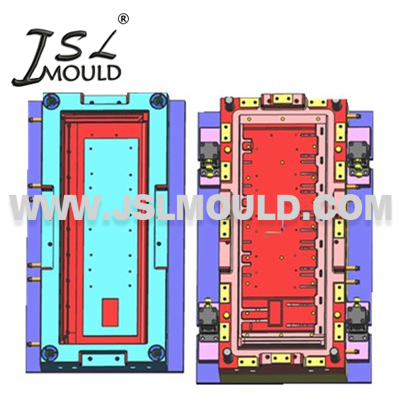

| Project Information | ||

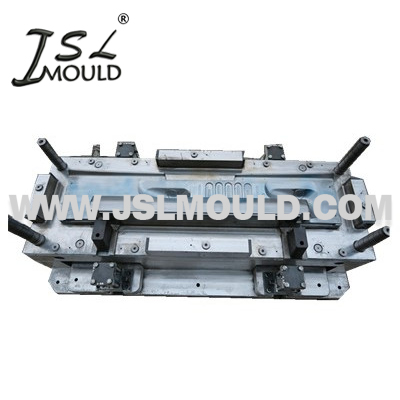

| Product Description | Part Name | House Roof |

| Part Material | SMC | |

| Part Size(MM) | 1227*421*36 | |

| Mould Steel | A plate | S50C |

| B plate | S50C | |

| Cavity Insert | P20 (HRC 28-32) | |

| Core Insert | P20 (HRC 28-32) | |

| Slider Insert | / | |

| Ejector Plate | S50C | |

| Spare Parts | S50C | |

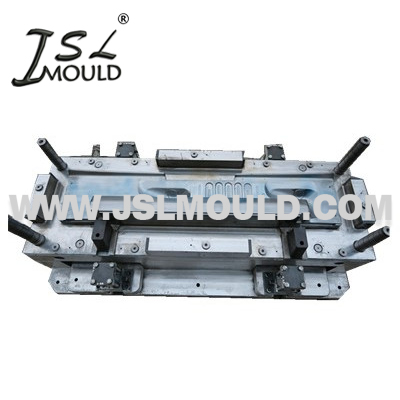

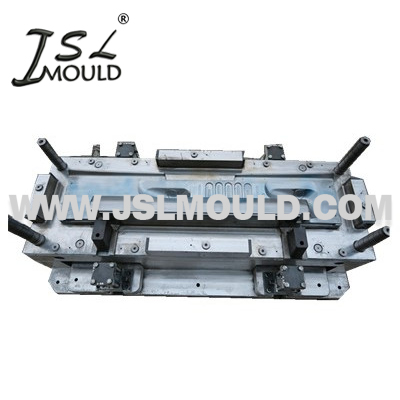

| Mould Description | Mould Size (L*W*H MM) | 1440*880*560 |

| Mould Gross Weight (KG’s) | 3740KG | |

| Mould Life Time (Shots) | 300,000 | |

| Mould Manufacturing Cycle | 60 days | |

| Surface Finish | polishing | |

| Runner Description | / | |

| Injection Gate Type | / | |

| Ejection System | Oil cylinder | |

| Cycle Time (Second) | 30s | |

| Compression moulding machine | 800T | |